Topic(s):

Titan Radial® Press Pipe – a gamechanger

Principal: Hastings District Council

Main Contractor: Fulton Hogan Hastings

Sub-Contractor: SCL Civil Works

Projects: Omaraunui Landfill / Howard Street

Product: Titan Radial® Press Pipe

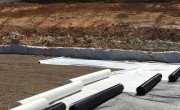

A new development of Omaraunui Landfill for the cities of Hastings and Napier requiring a new stormwater system is the first application of Humes’ new Titan Radial® Press Pipe in New Zealand a new technology that produces the pipe with a cast-in rubber collar, which is lighter and quicker to install, saving customers valuable time and money.

The main contractor for the project, Fulton Hogan, was given various options for the stormwater pipe required for the site. “When we quoted for this job in early 2023, we included our new Titan Radial® Press Pipe as an option,” says Craig Bryson, Account Manager for Humes. “We can offer our customers a much shorter lead time* for this pipe and the fact that it meets the same construction Standard, which was the requirement for this project, meant Fulton Hogan and SCL Civil Works were keen to try it.”

*It’s 70% faster to produce one pipe compared to our previous manufacturing technology hence a shorter lead time.

One of the SCL Civil Works team checks out the new rubber seals.

Mike Job, Managing Director for SCL Civil Works, the sub-contractor laying the pipe, said “the installation went really well. As far as we are concerned the use of this new pipe meant far less risk for us. With the cast-in rubber ring, there was no way we would have rings fitted incorrectly or hanging down between the sections, which can happen with other pipe options. This pipe gives us a nice tight seal meaning less risk - and it’s much quicker to install.”

Mike says the Humes support for the first installation of Titan Radial® Press Pipe was great. “Craig and a number of others from Humes came to the site to help with the first installation to make sure everyone knew what to do. This gave our team confidence when laying the new pipe.”

Regan Leahy, Project Manager for Fulton Hogan says, “this pipe is different to what we are used to, but the SCL guys said that it was much quicker to install, speeding up the process and our time on the job. The feedback all around was really good.”

It didn’t take long for the word to get out about Humes’ new Titan Radial® Press Pipe. “A little while after the installation at the Omaraunui Landfill, I received a call from Aaron Bidlake from Fulton Hogan who wanted to use the Titan Radial® Press Pipe at a new residential subdivision in Howard Street, Hastings,” adds Craig.

“We had heard through our teams that the Humes Titan Radial® Press Pipe was much quicker to install so we contacted Craig from Humes and arranged to try it at a subdivision we were working on. It is definitely quicker to install, I would say about half an hour per section. We’ve had the CCTV through the pipes and it looks really good. We are happy and would most definitely use it for future stormwater projects.”

“Our new pipe is not only easier to install for the contractors, being lighter and faster to produce, it also saves on transport charges and manufacturing costs therefore reducing our CO2 emissions,” adds Craig.

Some of the comments from the guys from CSL on site:

“I can’t believe how easy that was.”

“It works even better than we thought it would.”

“We're going to be able to lay much faster now!”

“ It’s a game changer.”

For more about the Humes Titan Radial® Press Pipe click here or contact us on Ph: 0800 502 112.