Topic(s):

Humes’ superior solution saves time and money at Waikanae

Humes were able to provide a solution that was not only cost effective for the principal; it was a better solution in terms of design and innovation used.

Project summary:

- Fast growing Kapiti Coast demanded higher water volumes

- Provide cost effective, technologically robust water system

- Total length of pipeline 8.5km

- Tight construction time (26 weeks) requiring high service levels for supplier

- Highly technical project requiring specific outcomes

For the last 20 years, the Kapiti Coast has seen a high population growth. In 1992 Kapiti Coast District Council (KCDC) recognized the growth and that the infrastructure needed to have capacity increased. By the mid 1990’s plans had been set for a new waste water treatment plant and a water supply source. In 2004, 450 new houses added to the demands on the Kapiti water supply.

"The Humes team has assisted in making a difficult project run extremely smoothly"

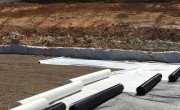

Previously the Waikanae River and catchment were the only source of water for the region. With this source running critically low, KCDC commissioned URS to design a borefield. Originally the 8.5km pipeline system was to be made up of a mixture of PE and uPVC pipe. The Humes option finally chosen by KCDC comprised of the following:

- Total uPVC 3.5km of 450mm S1, 2km of 375 S2, 3km of 300/250 S2

- Use of series 2 deflection joint technology combined with short pipe options

- Development of the 450 S1 Z seal ring socket for ductile fittings

The benefits:

- Faster installation, not having to work around PE welding contractors and maneuvering long strings of PE pipe

- Smaller machinery and equipment required

- Eliminated weld test costs

- 450mm S1 Z seal ring allowed socket to socket fittings to be used

- 375mm and 300mm S2 uPVC allowed for deflection joint technology use of socket to socket fittings

- Total savings to KCDC of over $100,000

The 450mm Series 1 rubber ring for ductile fittings was a world first and as such provided a challenge in providing the product never before produced. From conception to production the Humes team developed a fully functional solution in just 1 month.

KCDC said that the Humes team’s reaction to Brian Perry’s requests were extremely fast in delivering what they wanted, when they wanted it.

Derek Bilby, Wellington Manager of Brian Perry Civil said, “Both Todd Randell [Humes technical sales representative] and the Humes Kapiti Sales Centre team have shown commitment above and beyond the call of duty in assisting in solving site problems and delivering materials to site when required.”

“The Humes team has assisted in making a difficult project run extremely smoothly”, Derek concluded.

Humes’ current range of water products has always played a key role in providing solutions in technically challenging projects. With Humes’ commitment to developing and obtaining technology in the water supply industry, rest assured there are more solutions in the pipeline.